- Research areas : /it/ricerca-applicata/iprint/research-areas/

- Inkjet Training Center : /it/ricerca-applicata/iprint/inkjet-training-center/

- How to work with us : /it/ricerca-applicata/iprint/how-to-work-with-us/

- Digital manufacturing : /it/ricerca-applicata/iprint/digital-manufacturing/

- Project portfolio : /it/ricerca-applicata/iprint/project-portfolio/

- Equipment : /it/ricerca-applicata/iprint/equipment/

- Publications : /it/ricerca-applicata/iprint/publications/

- About us : /it/ricerca-applicata/iprint/about-us/

- Research areas : /it/ricerca-applicata/iprint/research-areas/

- Inkjet Training Center : /it/ricerca-applicata/iprint/inkjet-training-center/

- How to work with us : /it/ricerca-applicata/iprint/how-to-work-with-us/

- Digital manufacturing : /it/ricerca-applicata/iprint/digital-manufacturing/

- Project portfolio : /it/ricerca-applicata/iprint/project-portfolio/

- Equipment : /it/ricerca-applicata/iprint/equipment/

- Publications : /it/ricerca-applicata/iprint/publications/

- About us : /it/ricerca-applicata/iprint/about-us/

Smart Material by Inkjet

Summary

Advanced manufacturing

HES-SO Research Program / Young Researchers Projects (2021)

Adolphe Merkle Institute, University of Fribourg, Switzerland

Gilbert Gugler

Skills directory

January 2022 - January 2023

The present project is a first step toward the manufacturing of continuously varying gradient material with inkjet technology. The main objective is to build up basic understanding on multimaterial droplet interaction for creating tailored made surfaces. Through the vehicle of inks with different softness grades which are doped with mechanochromic additive, we have developed a multi-material inkjet platform, which allows to create gradient materials with new performance. The additive will help to characterize this new kind of materials on one hand and on the other hand it’s the start of creating new passive pressure and temperature sensors.

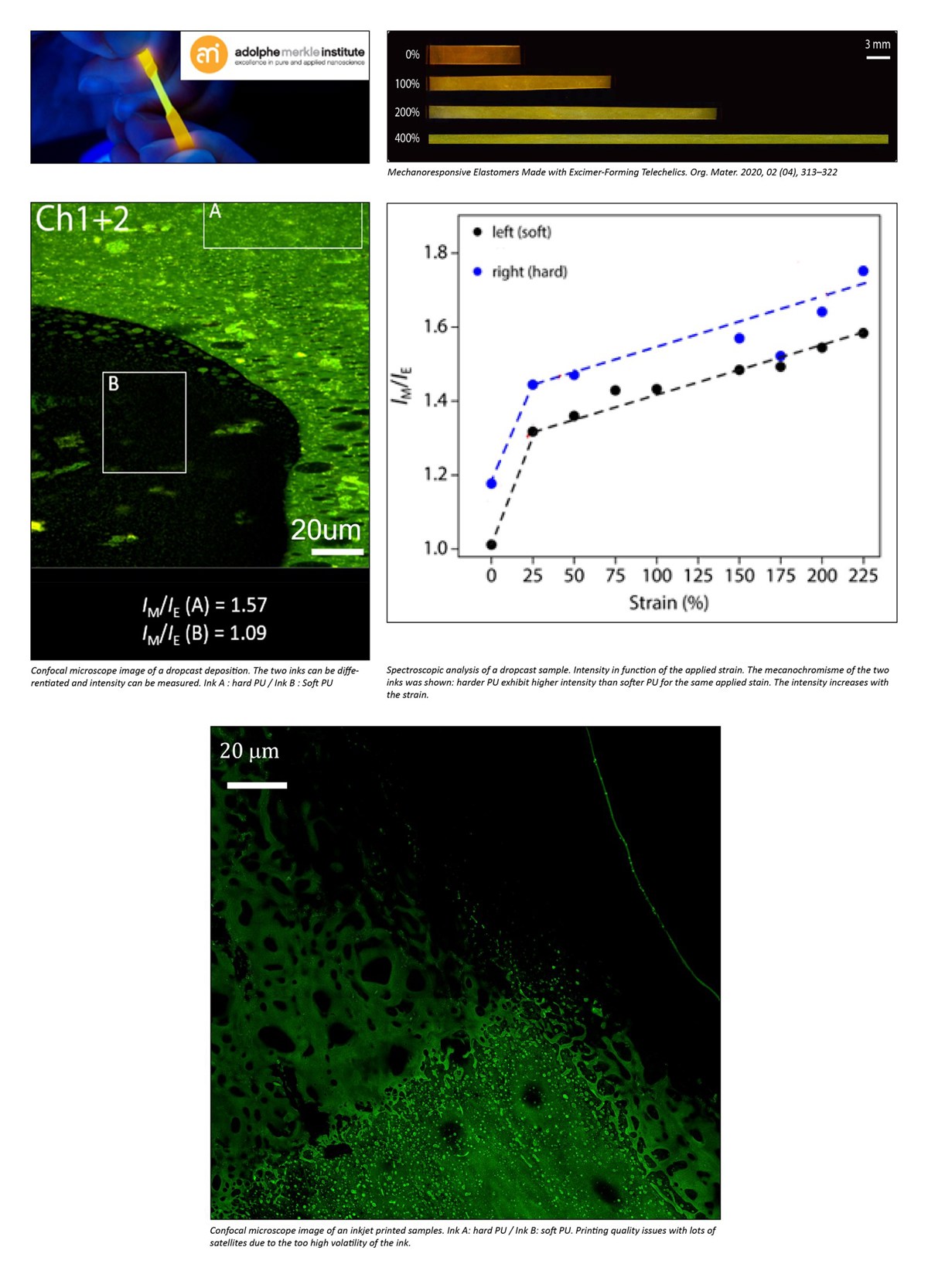

Smart-Inks containing dissolved Polyurethanes (PU) with different hardness grades (Shore 35-80A) were formulated. A mechanochromic additive developed by the Adolphe Merkle Institute, which changes its fluorescence absorption and color in response to mechanical forces (elongation) was added to the ink. This additive is a marker and has no impact on the properties of the PU. To ensure successful inkjet printing, the use of low-viscosity inks is required, which limits the current choice of materials.

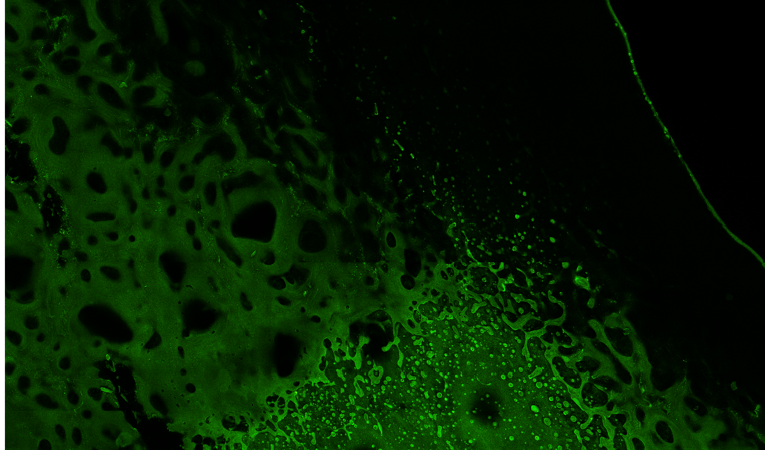

A big challenge was to find a suitable solvent compatible both with the additive and with commercially available inkjet printheads. A high boiling point solvent is preferred in inkjet to avoid drying of the ink at the nozzle. However, it turned out that a low boiling point solvent must be used due to the drying requirements of the additive. This resulted in a more difficult printing process.

A multi-material inkjet plateform was developed and printing process optimized, which allows to create gradient materials with new performances. Drops of selected inks were deposited by inkjet close to each other, then elongated up to 100% under the confocal microscope. The intensity of the mechanochromic additive measured with the confocal microscope under UV light is different for each PU. It is possible to know with very high precision the hardness of the material by measuring this intensity. This visualization will help to simulate the behavior of the drops to create new tailored material with high precision deposition and resolution.

More information